Case Study: Developing Automated Relay Test Boxes to Improve Plant Productivity

A large number of relay types, especially Clifford and Snell (now C&S Controls) D2600 series relays, are used across a broad spectrum of industrial control systems. Usage includes controlling the movement of reactor control rods in nuclear power stations.

Outage periods at nuclear power stations provide limited opportunities to carry out essential maintenance functions. Relay testing is an integral part of outage programming and takes a significant amount of time and effort.

Our customer has over 200,000 Clifford and Snell D2600 relays in use across their nuclear fleet, each of which performs an essential function in keeping plant safe and secure. Due to their vital role in plant protection, regular testing is required to confirm full functionality. The process for testing this equipment was manual, resulting in it being costly and time-consuming.

In order to reduce the man-hours involved, a solution was needed to automate the testing procedure. Automation of the test routine was also required to ensure consistent and repeatable results.

Decision-making process

Custom test solutions are designed and built in response to specific testing requirements. A feasibility study was held with our customer to identify the key requirements of the new relay test box. Robustness, ease of use, portability and accurate consistent results were highlighted as the priority factors in the design of a new unit. Cost-effectiveness was also of high importance.

A milestone system was implemented to track progress and a proposed design was agreed upon that met our customer’s requirements.

Solution

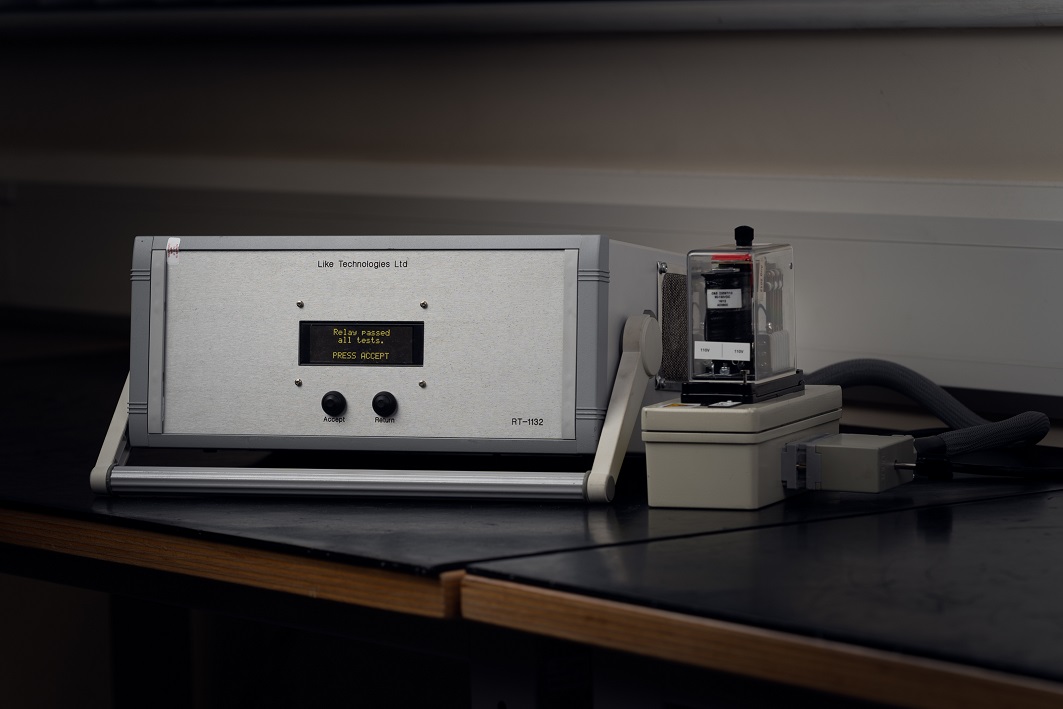

We were contracted to design and develop a test box in order to automate the process of relay testing. We designed and produced an automated relay test box for our customer, minimising the time required to test a multitude of Clifford and Snell D2600 series relays across their fleet of power stations, reducing costs while improving the accuracy of results and providing a greater guarantee of plant safety.

Designs were developed into a prototype unit that underwent initial testing to ensure full functionality and performance in line with customer and industry standards. The prototype was sent to one of our customer’s sites for final testing. This confirmed the unit to be fit for purpose and easy to integrate into existing plant infrastructure. Trials of the prototype units proved that considerable savings could be achieved.

The project was then able to enter production. Initially, products were supplied for use at one power plant, but after proven success in boosting efficiency and reducing cost, more orders have since been filled across the fleet.

Results

The automated relay test box has minimised the time required to test the multitude of Clifford and Snell D2600 relays on the plant, thereby reducing cost while also improving the accuracy of results and providing a greater guarantee of plant safety in a much shorter timeframe. Ultimately, the relay test box has become an indispensable piece of equipment in ensuring plant safety across our customer’s fleet.

Consideration was made during the design stage to allow for the testing of other relay types and manufacturers by making the test box generic. Additional relay pods can be supplied if requested. Please contact us for more details.