Business Development

Progressing into 2024

Progress is what we will achieve in 2024. Our projects, and people, will progress as we work with new and existing clients and partners. Reminded of Audi and their series of adverts relating to progress, which you can watch here, the statements that “progress is anything but a straight path” and “making progress requires an open mind” are relevant…

Read MoreSigning off for 2023

We’re publishing our final blog of 2023 feeling a sense of achievement. Thanks to those of you that continue to read them each month. In the past 12 months, we’ve extended contracts, received orders from new customers, increased the headcount in the workshop and raised thousands of pounds for a large and small charity. Things feel…

Read MoreLike for Like

Like for Like is what we meant when we named the business. We set out to either repair or replace electronic equipment, like-for-like. We were founded in 2006, in response to the need for obsolescence management solutions in industry and under the principles of sustainability. As the company has grown, we’re also able to create new…

Read MoreWe’re a finalist!

Opening our email inbox this time last week we were shocked to find out that Like Technologies are a finalist in the BECBC Awards 2023! I mean, we knew we’d submitted an entry and selected a category that gave us the opportunity to showcase our strengths, but as can often happen, the time and effort…

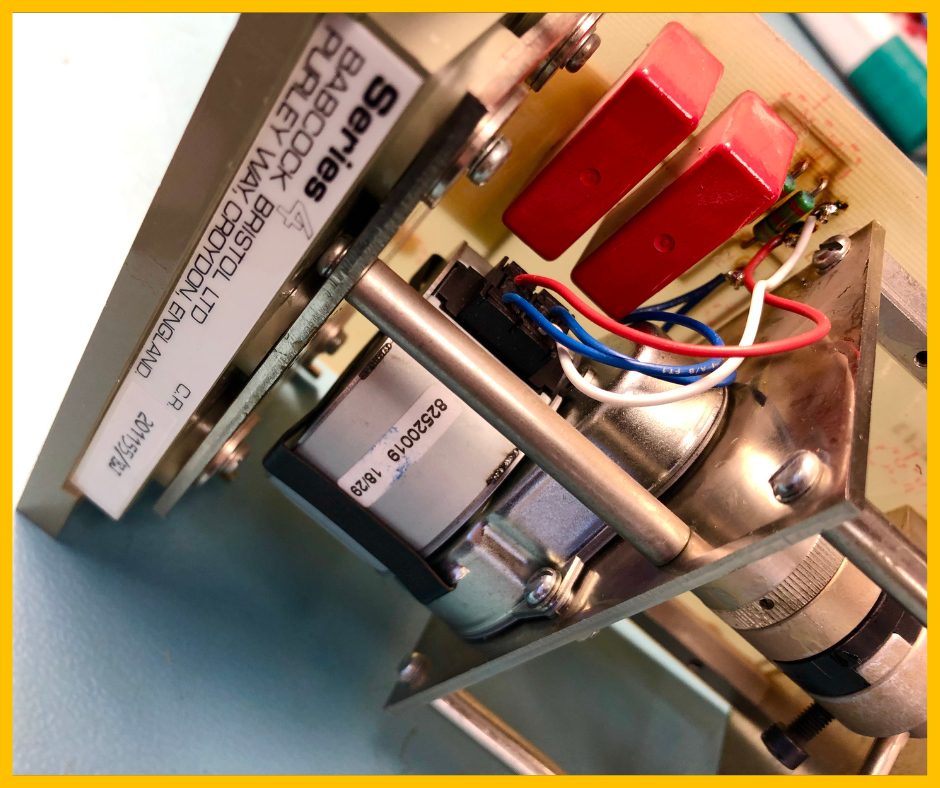

Read MoreRefurbish to Sustain

At Like Technologies we have two company meetings per year. It’s an opportunity for the team to come together, share knowledge and provide an update from each department. At the most recent one, held in May, one of our engineers Simon, updated us on an ongoing project that he would describe as ‘important but not complicated’. The…

Read MoreSearching for the ‘doing’ words

We’ve spoken about our hardware and software engineers before and if you look at the case studies on our website, they’re likely to be about our workshop team. It can be trickier to tell you about the work our IS team get up to but that doesn’t mean it’s any less important. They’ve recently supported…

Read MoreJust two, not fifty-two.

At Like Technologies, there’s not a lot we say no to. Often, an existing client will ask us to reproduce a product and our answer will be along the lines of, “let’s take a look first, but yes, I’m sure we’ll be able to help you.” In the most recent case, we were asked to…

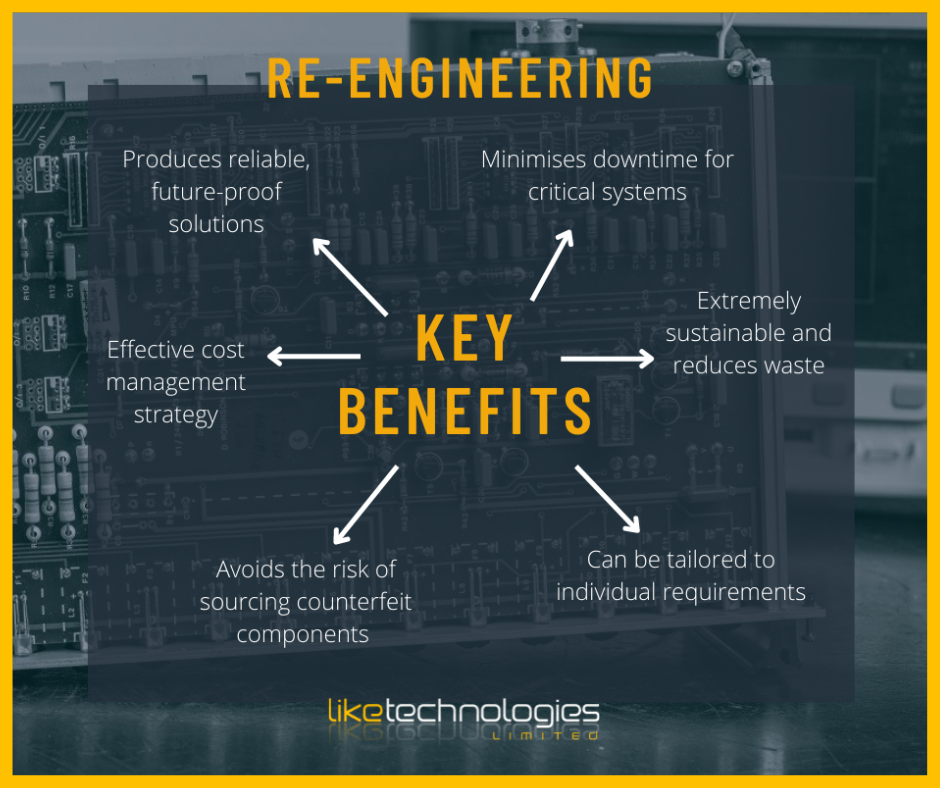

Read MoreWhat is re-engineering?

Companies working within industrial environments are increasingly under pressure from the demands of modern-day and the desire to have solutions to a problem at the click of a finger. Rising customer demands puts pressure on these industries specifically when output and performance needs to be at a maximum but downtime is not an option. There is…

Read MoreWhat happens when your original equipment manufacturer no longer supplies your equipment?

It’s common within industrial environments to still operate legacy equipment. To update existing equipment can be time-consuming and costly. Yet what happens when your original equipment manufacturer (OEM) no longer supports or supplies the equipment you use? Ageing and obsolescence of said equipment then becomes a risk to your business, as it may not be…

Read MoreInternational Women in Engineering Day 2022

To celebrate this year’s International Women in Engineering Day we want to shine a spotlight on some of the incredible women that work within our team. Although a small company, we are proud to say that 29% of our team are female. A higher statistic than the 19% overall UK average of women working in…

Read More