Obsolescence Management

Statutory Outage

It’s quiet in Wenning House as the team are on site supporting a statutory outage. As you’ll be aware, obsolescence is a growing and significant threat within the power generation and nuclear industries in the UK. Strictly regulated, highly secure and responsible for providing the country’s light and warmth, there are real challenges when it comes…

Read MoreShowcasing Capability

How do we showcase our technical capability? That’s the question we’re starting to think about as we move towards the end of the year and into 2025. We’re planning to get to more events to meet you in person and invite some of you in for a tour of the workshop in addition to our…

Read MoreManaging Obsolescence

How can you plan for and tackle obsolescence more efficiently? That was the question we discussed for the latest edition of Operations Engineer. Alongside AVEVA and ABB we explored solutions that would support industrial operators and plant engineers that have to deal with the threat daily. We were asked to think of an example where equipment,…

Read MoreProblem Solvers

We’re talking about our people this month. Our workshop team has continued to expand over the past 12 months and we’re working on multiple projects in-house, supporting our clients on site and delivering comprehensive training plans alongside industry masterclasses in our local colleges. Did you know we’ve been working with Relay Test Boxes for over 10 years?…

Read More“well that’s what you’ve always done”

Earlier this year we were invited to help inform Government Policy on Resources and Waste Strategy by the Department for Environment, Food and Rural Affairs (Defra). The topics covered include circularity and sustainability of procurement and operations, our opinion on consumer trends, how we adapt to changes in the policy landscape related to resource and waste, and…

Read MoreWhat is…?

At Like Technologies, we like it when people ask questions, it’s something we actively encourage across our engineering, administration and leadership teams. Here, we’ve summarised the most common questions you’ve searched for (and found) on our website in 2022. What is the Difference Between Re-engineering and Reverse Engineering? Re-engineering and reverse engineering are two technical…

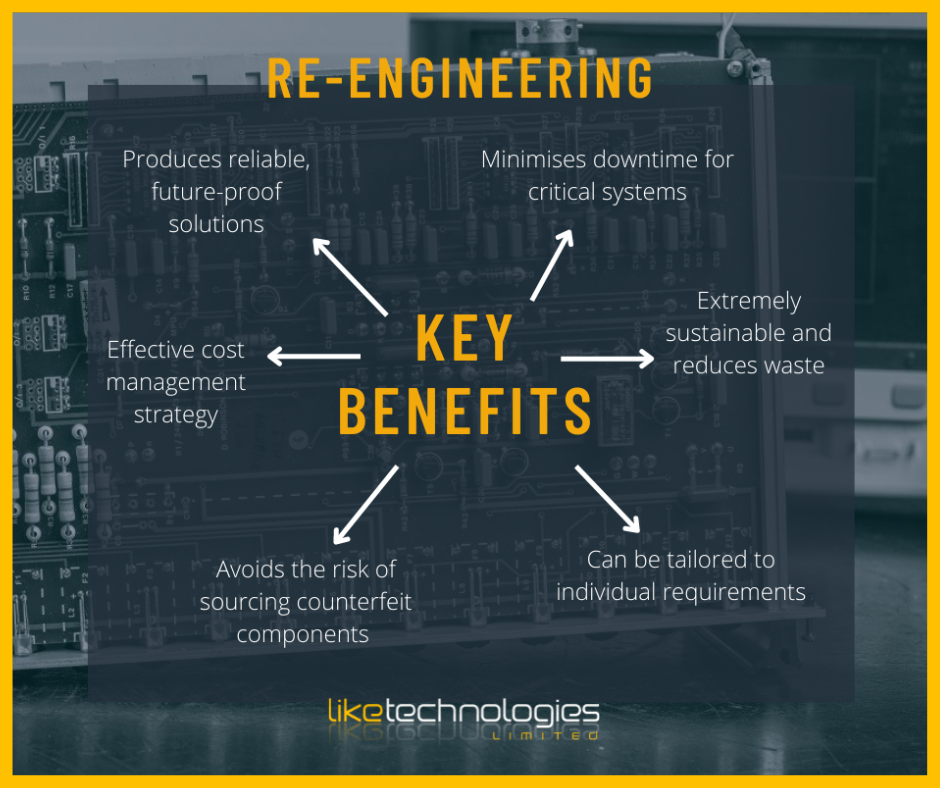

Read MoreWhat is re-engineering?

Companies working within industrial environments are increasingly under pressure from the demands of modern-day and the desire to have solutions to a problem at the click of a finger. Rising customer demands puts pressure on these industries specifically when output and performance needs to be at a maximum but downtime is not an option. There is…

Read MoreWhat happens when your original equipment manufacturer no longer supplies your equipment?

It’s common within industrial environments to still operate legacy equipment. To update existing equipment can be time-consuming and costly. Yet what happens when your original equipment manufacturer (OEM) no longer supports or supplies the equipment you use? Ageing and obsolescence of said equipment then becomes a risk to your business, as it may not be…

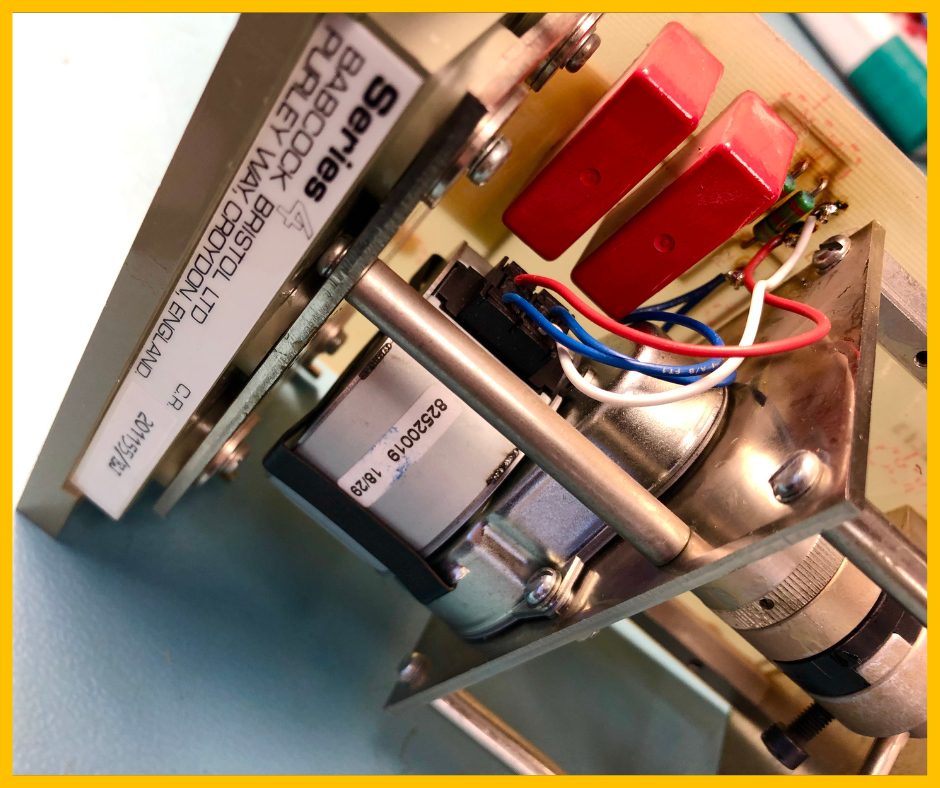

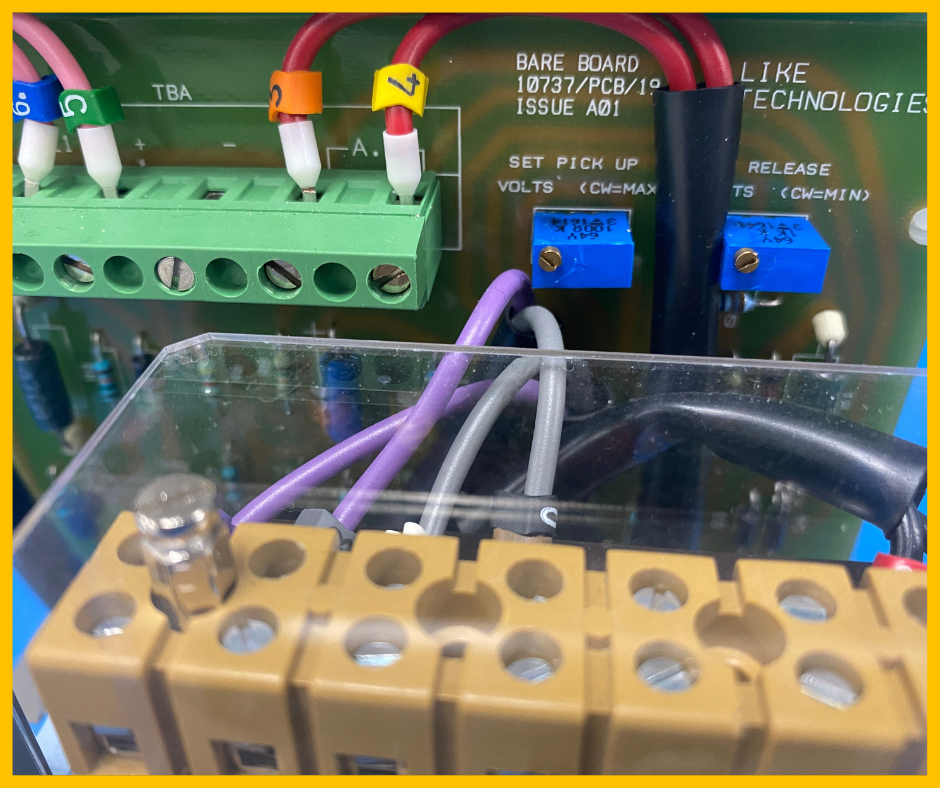

Read MoreCase Study: Under Voltage Relay Remanufacture

Companies working within industrial environments are under pressure from the demands of the modern-day when output and performance need to be at a maximum, but downtime is not an option. There is increasingly a need to improve the performance of existing equipment as an alternative solution, that’s where re-manufacturing comes in. One of our customers has…

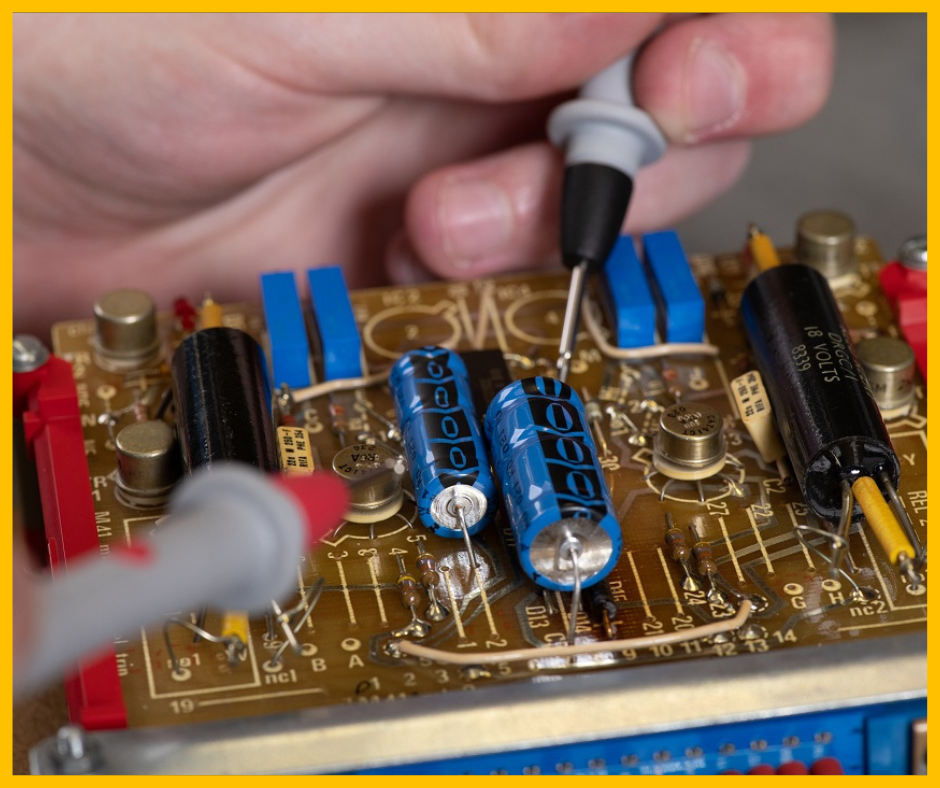

Read MoreHow Repairing Electronic Modules Keeps The Power Generation Industry Going

The power generation industry, and more specifically, nuclear power often relies on legacy software and systems to keep their sites running. These industries constantly face pressure to extend the functional lifetime of their older equipment, more specifically electronic modules due to the huge investment and upheaval it would take to simply replace the entire system.…

Read More