Pulse to Pneumatic Project – Bespoke Hardware Design

Our customer, EDF at Torness, were experiencing some issues on installation of their new Pulse to Pneumatic converters at Torness Power Station.

They had replaced their existing converters from the pneumatic/mechanical originals with a much smaller electronic alternative. These ageing pieces of equipment had a high failure rate and were more costly or very difficult to replace.

“During installation of new Pulse to Pneumatic (P2P) converters, which are electronic equivalents of the Babcock Bristol YSL P2P units, at Torness Power Station, we started to experience problems during commissioning with pulse degradation from the BBL Series 4 control cards, which were involved in the pulse generation to allow pneumatic positioning of Air Operated Valves (AOV’s). This issue seemed to affect predominantly long length loops on site, and went previously unnoticed on shorter length loops.”

Like Technologies, due to their experience with the BBL Series 4 control system, were asked to assist and were given the following remit;

1. Investigate why the degradation in the control pulses was prevalent on long length control and instrumentation (C&I) loops.

2. To produce a solution, universal for all loop lengths, compatible in both manual and auto mode of operation, that would correct the control pulse quality and return correct control pulses on site to the new P2P units.

Designing a bespoke electronic solution to solve the problem

After several site tests and workshop tests, it was concluded by Like Technologies that the C&I loop large cable capacitance on the longer loops was interfering with the BBL Series 4 Auto control card pulse generation transistor switching rates. The new electronic P2P units were more susceptible to the pulse degradation as it required definite switching voltages, whereas the stepper motors on the original YSL units were more tolerant to a poor quality waveform.

We also examined why the manual BBL Series 4 card did not suffer from the same pulse degradation issue as they seemed to have identical circuits. The checks and tests revealed that the manual pulse generation card had a slightly different design of pulse generation circuit that was not affected by the cable capacitance.

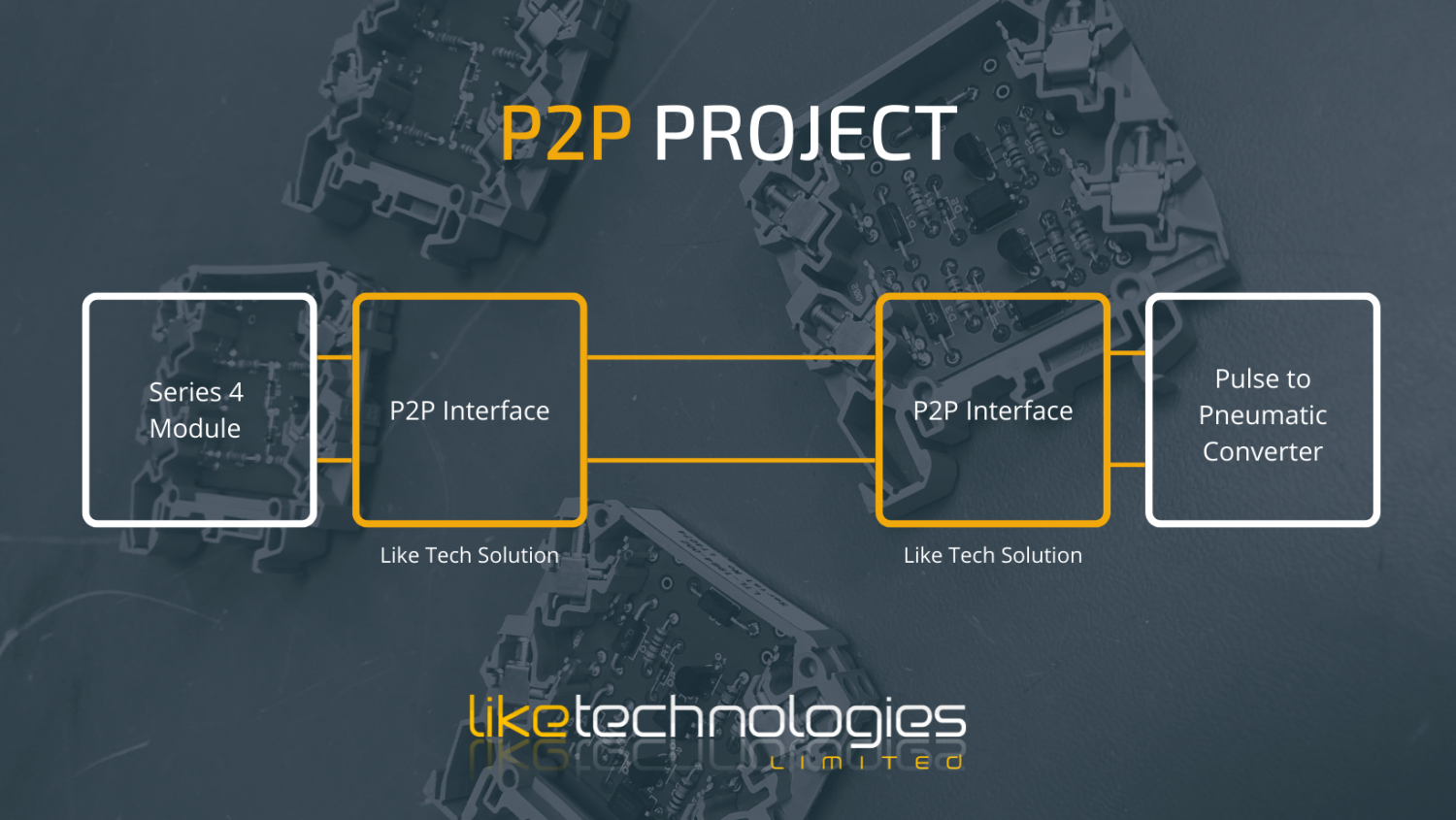

The solution proposed, after prototype testing and encapsulation in a housing was two-fold;

1. An interface unit fitted at the BBL Series 4 panel control card output connections to isolate the Series 4 control card from the cable capacitance.

2. An interface unit fitted at the new P2P units to replace what was a diode/resistor network.

Both these units also afforded some additional voltage spike suppression on the circuit to protect the interface electronics.

Trials on an actual loop were carried out on site and functioned as per design. We were then able to manufacture these interface units for both operating units on site.

Known as the Pulse to Pneumatic Interface, they have been fitted and tested, with all loops now operational across one of the sites units with the other unit to be completed during the next outage.

Challenges we overcame

- Determining what was causing the degradation in the control pulses.

- Ensuring the P2P Interface accurately converted pulses from the Series 4 module, and was compatible with the new P2P converter.

- Manufacturing a product that was small and compact enough to fit inside the existing cabinet.

Speaking on behalf of EDF, John McKenzie said;

“Like Technologies produced various reports at appropriate stages in the project to allow EDF to track and understand the progress being made, and met regularly with EDF to discuss outcomes.

Drawings for the new interface modules were produced and provided to EDF as well as QA plans to manufacture and test prior to shipping to site. The units were allocated a site catalogue ID to secure QA with future purchases.

EDF were very pleased with the way Like Technologies handled the project and communicated well at each stage. The final solution is well-designed and is a practical retrofit to our control loops which correct the pulse degradation problem.”

At Like Technologies we are uniquely positioned to provide, and create bespoke hardware and software solutions that extend the functional life of your legacy equipment when interfacing with newer technology.

Get in touch today by visiting our contact page or calling us on 01524 811383.