Repairing PCBs to Reduce Electronic Waste

Repairing printed circuit boards (PCBs) is a crucial way to reduce the need to recycle or dispose of electronic waste. In 2021, it was estimated that the world’s total amount of electronic and electrical equipment waste would be 57.4 million tonnes. This gigantic figure resulted from limited repair options, shorter product lifecycles and increased consumerism.

In a typical industrial environment, damaged and defective PCBs are often replaced so the system, machine or process can continue. Over time, the faulty PCBs can mount up and in a worst-case scenario, can end up in landfills. However, this is avoidable as faulty PCBs can often be repaired and reused. This method is commonly used in military, transport and power generation sectors. These sectors often experience pressure to extend the lifetime of older electronic components due to huge investment in infrastructure and the problems of obsolescence.

Repairing industrial electronic equipment rather than simply replacing it can help with efficiency as well as sustainability. Benefits can include cost savings, extended equipment life and crucially removing the requirement for costly and time-consuming modifications to existing systems. Read on to discover more about repairing PCBs.

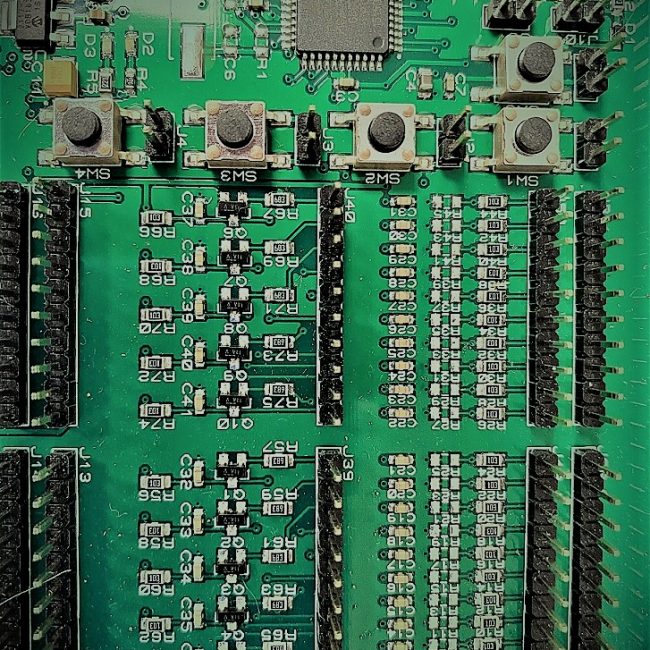

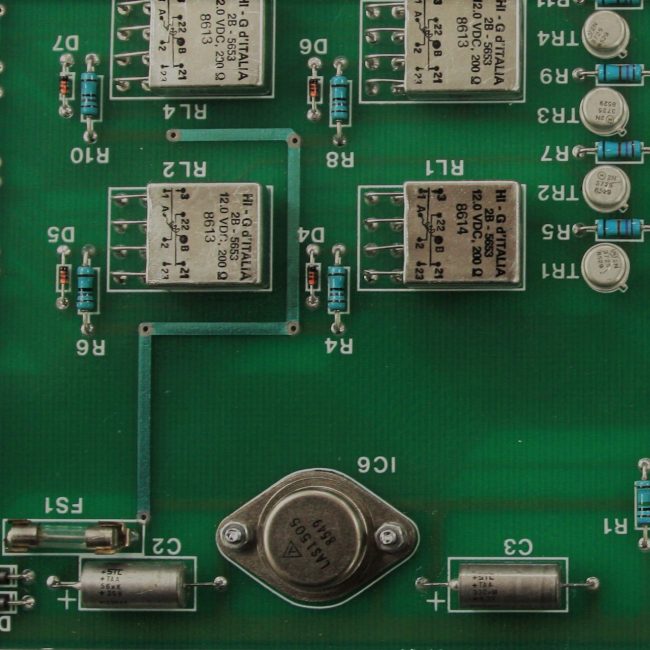

Printed circuit boards in action

PCBs are constructed from glass-enforced plastic and use copper wire which connects components, forming a circuit. PCB components are soldered to a board, which electrically and mechanically fastens them to the overall circuit. Components can include batteries, resistors, LEDs, transistors, capacitors and more. These will inevitably fail over time. It only takes one component to stop a PCB from working, which can stop an entire industrial machine or production process.

Can industrial PCBs be repaired?

When a PCB fails, operators often look for a modern replacement. This is not a sustainable approach and a replacement item may also be obsolete or too expensive. With repair or remanufacture, PCBs can be made like new again. The original functionality can be returned allowing it to be fitted back into the system. However, repairing or attempting remanufacturing of an existing PCB should only be done by trained and experienced professionals. An expert approach is needed because before a PCB can be repaired, it is important to diagnose the fault and understand why it has failed.

Why do Printed Circuit Boards fail?

PCB failures can be attributed to a number of causes, such as physical damage, environmental factors, thermal stress and most commonly, failure of individual components.

1. Physical Damage

PCBs can fail after being subject to physical damage such as pressure or shock. Examples of this could include being dropped, being hit by another object or becoming damaged during fitment or removal.

Physical damage can be remedied through remanufacturing or if deemed appropriate repair of the PCB using industry-approved practices. Damaged sections of the board can be removed and replaced with new material that allows tracking and components to be replaced returning the operation of the unit.

2.Environmental Factors

PCBs can fail if they are subjected to harsh elements outside of the boundaries of their design intent. These elements can be temperature, dirt, debris and moisture.

3.Thermal Stress

Excessive heat or cold can cause thermal stress to the components, the soldered joints on a PCB or the PCB itself. This can be caused by poor design or external stresses, for example, EOS (Electrical Overstress) applied to the PCB during normal operation.

4.Component Failure

The above issues are contributory factors linked to component failure. Certain components age naturally and eventually fail, examples of these are electrolytic capacitors and mechanical items such as switches, motors etc. Latent manufacturing errors can also cause failures, especially improper handling of components at the assembly stage. The main cause of these issues is ESD (Electrostatic Discharge).

We are industrial PCB repair and refurbishment specialists

At Like Technologies, we repair printed circuit boards and industrial electronic equipment down to component level, increasing sustainability, convenience and cost-effectiveness for our customers.

Are you are looking for options to extend the life of PCBs? We have an advanced workshop with repair and test technologies which allow us to carry out repairs on a wide range of equipment from manufacturers such as:

- Babcock Bristol

- Kingshill

- Protech

- Penny & Giles

- Siemens

- GEC

- GEM

- Honeywell

With more than 15 years of experience, Like Technologies has the technical knowledge and capability to offer printed circuit board repair, modification, final test and assembly services. We repair large quantities of PCBs every year that might otherwise become industrial electronic waste.

For many companies, electronic repair is the most intelligent and sustainable option. This keeps electronic modules out of the industrial waste stream, helps to improve machinery/plant efficiency and is cost-effective.

We are always keen to speak to new organisations where our expert industrial PCB repair and testing services can provide bespoke, value for money solutions. Get in touch today by visiting our contact page or calling us on 01524 811383.