What is re-engineering?

Companies working within industrial environments are increasingly under pressure from the demands of modern-day and the desire to have solutions to a problem at the click of a finger. Rising customer demands puts pressure on these industries specifically when output and performance needs to be at a maximum but downtime is not an option.

There is increasingly a need to improve the performance of existing equipment as an alternative solution. In these instances to replace older hardware or software would be timely and extremely costly, often these companies do not have the resource availability to consider shutting down their operations to install new equipment.

Why might you consider re-engineering?

The reasons to consider re-engineering usually include:

- To improve a particular area of performance

- To improve functionality

- To reduce operational costs/increase efficiency

- To add new features to the original design

How does re-engineering solve the problem?

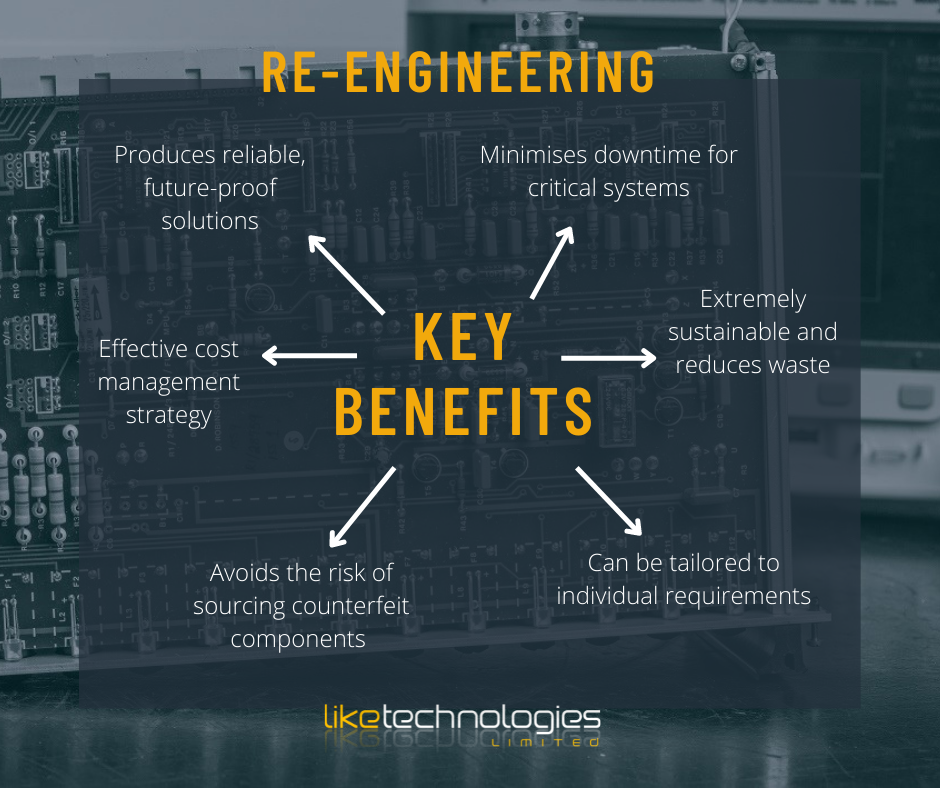

Re-engineering can be an excellent alternative to a complete equipment overhaul. The process involves taking the current design of a device or system and redesigning certain aspects of it to improve efficiency and reduce failure rate.

In many cases the original design process documentation for the equipment is outdated, or there is no remaining documentation at all. This calls for expert skills in research, evaluation and development of newer technologies that can be incorporated into existing products in order to enhance their functionality.

Sourcing out of date or obsolete parts for ageing equipment is often impossible. Original parts may no longer be being manufactured or the manufacturer themselves might not be in operation at all. Re-engineering provides a practical solution to maintaining safe industrial operation.

Another advantage of re-engineering is the ability to utilise some emerging technologies without changing functionality of the existing piece of equipment or software. This might mean developing a new piece of software that could link an older system with a new one.

Like Technologies re-engineering services

At Like Technologies we develop new technologies that allow your business to maintain productivity without having to replace an entire system. The service we offer is customised, we will analyse individual products failure rates or patterns and evaluate the solutions available to the existing design.

We will then create a prototype that goes through extensive testing to enable us to produce a final product for manufacture.

Click here to read our recent case study; Evaluation and refurbishment of the Babcock Bristol Ltd Series 4 Module. Alternatively, find out how Like Technologies can help you maintain safe industrial operation by visiting the services section on our website.